|

Dear Sir or Madam,

Today we would like to inform you about newly published FOSTA final reports from the fields of mobility, construction and mechanical engineering.

These and all other FOSTA reports can be found at shop.stahldaten.de

We would like to wish you now an interesting reading.

Your FOSTA team

| P 872 - Development of a simple quality assurance test for the application of high frequency mechanical impact treatment techniques

The effect of increased fatigue strength by application of high frequency mechanical impact treatments (HFMI) could be verified on several types of welded joints, which are appropriate for this kind of post-weld treatment. In addition to accepted guidelines for the fatigue design of treated welds, the qualification of users as well as the qualification and quality assurance of the equipment is necessary for a reliable application of these techniques. Therefore, generally three methods are generally considered. In this study and in a parallel running DASt research project, specimens have been used to verify the efficiency and feasibility. read more

|

| P 1020 - Practice-oriented welded high strength steel connections – Refinement of design rules and optimization of processes considering ductility properties

The use of high-strength structural steels in steel and plant construction is limited in its economic viability due to various corrections in design and execution. The aim of the research project was therefore to create a basis that would lead to a significant improvement in the operating conditions of high-strength steels in welded joints. The need to improve the technical rules for design and execution occurred for a number of reasons. For example, the permissible weld stresses of matching and overmatching joints are too conservatively determined for many joint types and combinations of base and filler metals. The correlation coefficient βw was determined for the worst case where longitudinal fillet welds are subjected to parallel shear. For a large proportion of welded joints, it is not necessary that the strength of the base metal is reached or even exceeded. This applies, for example, to fillet welds of welded I- and box sections, hinged end plate connections, butt joints in areas of low stress and in many other cases. read more

|

| P 1042 - Fatigue strength of hot-dip galvanized composite dowels in composite bridges

Investigations in recent years have shown that the hot-dip galvanizing of steel components in bridge constructions provides economic and ecological advantages. It has been showed that the first corrosion protection over the 100-year service life of a bridge can also exist in an environment with high corrosivity, so that no major corrosion protection maintenance measures are required. At the same time, another innovative solution was developed to increase the efficiency of composite bridges. Based on several research projects and an initial application in 2003, composite dowel strips offer an economical solution for shear connections between steel beams and concrete plates in composite bridge structures. Continuous improvement and further development finally led to a general technical approval applied for by FOSTA and granted by DIBt in Germany. Since then, numerous bridges with this new technology have been built in Germany and abroad. However, hot-dip galvanizing may not be applied to bridges with composite dowel strips, since the effects of hot-dip galvanizing on the fatigue strength of flame-cut composite dowels are unknown. The required fatigue test in accordance with DIN EN 1993-1-9 can therefore not be performed properly at present. read more

|

| P 1132 - Fatigue behaviour of hollow sections joints and high strength steel

To enable lightweight design, also fatigue loaded structures are more and more made of high strength steels. The K-joint with gap is the favored joint configuration in lattice girder design. Therefore, existing design rules must be extended by larger wall thicknesses and high strength steel grades to facilitate the application and design of such joints. The experimental test program comprehends a total of 55 fatigue tests on K-joints made of rectangular hollow sections (RHS) and circular hollow sections (CHS) of different dimensions made of S355, S500 and S700. Small scale specimens are examined at TNO, Delft on a test frame with single acting load cylinders. Test on large scale specimens are carried out at KIT in Karlsruhe on a specially made rigid test frame. read more

|

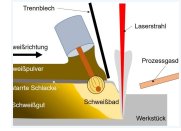

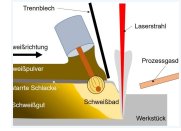

| P 1151 - Testing of Laser Submerged Arc Hybrid Welding for Thick Steel Appplications

The previous series of investigations on laser submerged arc hybrid welding have clearly demonstrated the fundamental usefulness of the newly developed process variant. The achieved weld seam qualities in positional opposition of joint welds using both laser beam types (CO2 and solid state) are more than satisfactory in the context of the investigations carried out. Sheet thicknesses of up to 50 mm could be joined reproducibly with low porosity.

The aim of the current project is the optimization and homogenization of the mechanical-technological characteristic values of joint welds in position-counter- location technology over the seam depth, based on the testing of suitable wire-powder combinations. As laser beam source a solid-state laser is used, which provides a spot diameter of 0.4 mm with the applied optical components. In the same step, the increase in process stability compared to slag running forward into the laser base point will be investigated by testing correspondingly tough and current-carrying welding powder variants. read more

|

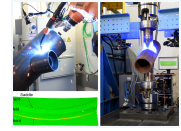

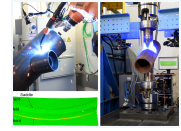

| P 1178 - Quantifying the effects of manufacturing automation and internal welding on the fatigue resistance of circular hollow section joints for offshore wind energy converters

The development within the offshore wind sector towards more powerful turbines combined with increasing water depth for new wind parks is challenging both the designer as well as the manufacturer of bottom fixed support structures. Besides XL-monopiles, the market developed an innovative and economic jacket support structure, which is based on automatically manufactured tubular joints combined with standardized pipes. Besides the improvements for a serial manufacturing process the automatically welded tubular joints show a great potential in terms of fatigue resistance e.g. due to a smooth weld geometry without sharp notches. However, these benefits are not considered yet within the fatigue design process of automatically manufactured jacket substructures according to standards and guidelines due to the lack of suitable S-N curves. read more

|

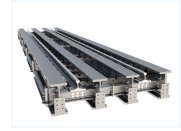

| P 1185 - Application of hot dip galvanizing on temporary bridges for the German Railway

DB Netz AG uses temporary bridges with different spans and construction methods during temporary construction work on and alongside railway lines to intercept the tracks. The service life of the bridges is generally between several days and a maximum of three years. The need for auxiliary bridges is great, as many bridges need to be repaired at present and in the near future and numerous new ones are to be built. The corrosion protection currently used consists of an organic coating, which often has to be repaired due to high mechanical stress caused by assembly and transport in order to avoid corrosion damage such as under-rusting or pitting and the associated weakening of the material. In addition, a high repair rate is associated with high expenditure and resource consumption. Hot-dip galvanizing is a well-known corrosion protection system, with high advantages concerning durability and stability. With research results of the last few years on the influence of hot-dip galvanizing on fatigue strength the basis for an application under cyclical load was also created. read more

|

|

|

|