|

Dear Sir or Madam,

Today we would like to inform you about newly published FOSTA final reports from the fields of mobility and construction.

These and all other FOSTA reports can be found in the shop of stahldaten.de at

https://shop.stahldaten.de

We would like to wish you now an interesting reading.

Stay healthy!

Your FOSTA team

|

|

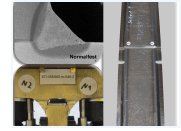

P 1055 - Development of ultra-high-strength steels for alternative heat treatments and for the cold forging of parts in the powertrain of passenger cars

The increasing demands in the passenger car sector for safety, comfort and driving performance have led to a continuous increase in vehicle weight in recent years. New lightweight construction concepts are needed to meet this trend so that future developments in driving performance can be achieved while at the same time reducing CO2 emissions and fuel consumption. Based on the current state of the art, approaches are made in the areas of material and design lightweight construction as well as production and concept lightweight construction. Within the scope of the present research project, new steels and/or an adapted heat treatment for components used in the powertrain were developed. The focus was on lightweight material construction. read more

|

|

P 1056 - Intelligent lightweight design through multicomponent proceseses

The weight of powertrain components has been continuously reduced by load-adapted design and through the materials savings achieved by this in areas with low stress. With the consistent increase in the power density and the associated reduction in weight, additional potential is available for the intelligent lightweight design of powertrain components in future. Significant optimization potential may be available in part design, material, heat treatment as well as the production and joining processes used. By combining various production processes and materials, the different requirements placed on various component areas are fulfilled. This enables lightweight design which is adapted to the specific load and is cost-efficient. read more

|

|

P 1057 - Lightweight design through targeted generation of local part properties with optimized forging and machining processes

This project aims at closing the existing gap between the definition of local component properties, in particular with regard to strain hardening, internal stresses and load-related fiber flow.Aiming to ensure these properties through optimised forming and machining processes as well as the development of steel materials with properties suitable for the process (cold formability, yield strength, strain hardening, machinability). A further goal of this subproject was the development of an efficient methodology for the virtual design of robust forming and machining processes taking into account optimal local component properties. read more

|

|

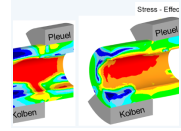

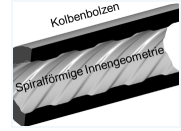

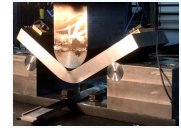

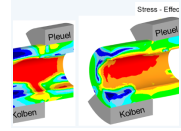

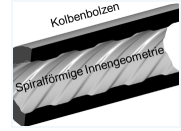

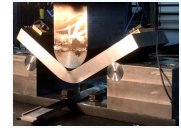

P 1058 - Lightweight design through targeted generation of local part properties with optimized forging and machining processes

As part of the research network “lightweight forging”, the Sub-project 4 “Extending technological boundaries by forming in different temperature ranges” investigated three demonstrator parts that were manufactured through fundamentally different processes of bulk metal forming in diverse temperature ranges. The content of the first work package consisted of the investigation of manufacturability of a piston pin by Ironing and the optimization of a spiral inner contour of in terms of its lightweight potential compared to a conventional cylindrical inner contour. In the second work package of the subproject, the focus was on the production of a gear shaft, also by a process of cold bulk forming, namely forward rod extrusion. read more

|

|

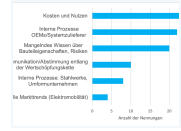

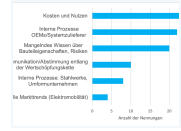

P 1059 - Innovation transfer, technical potential assessment and lifecycle analysis

Within the research network lightweight forging, SP5 assumes a comprehensive function by contributing aspects, which are downstream from the viewpoint of the development of the new components, e.g. the economic implementation as well as sustainability of lightweight innovations. This project focuses on an analysis of the industry level innovation system as well as the innovation barriers in the process chain, an evaluation of the potential of the primarily weight-reduced reference components, an analysis of the secondary weight saving potential and a life cycle analysis. In the project, innovation processes in the sectoral innovation system of massive lightweight forging were scrutinized. On this basis, innovation barriers were identified. One example are established routines in steel and forming companies. System suppliers and OEMs often do not possess sufficient knowledge about the possibilities of new materials and component designs. read more

|

|

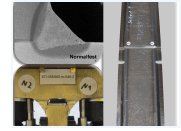

P 1154 - Investigations in composite forging for hybrid and same type material combinations

As a part of the research network “lightweight forging”, the Sub-project 6 “Compound forging of similar and dissimilar material combination” investigated the manufacturing of two hybrid wheel hubs made of steel-aluminium and steel steel by compound forging. The central question is to what extent two materials can be simultaneously formed and joined by using compound forging for the manufacturing of hybrid components and the associated use of material-specific advantages such as lightweight construction or increased performance. read more

|

|

Forschungsergebnisse aus den Bereichen Mobilität, Anlagen- und Maschinenbau, Bauwesen

|

|

P 960 - Adhesive bonding of batch hot-dip galvanized assemblies

The main objective of this research project was to develop a concept for reliably bonding batch hot-dip galvanized semi-finished assemblies with structural adhesives for commercial vehicles and the building and construction industry. The focus was in particular the determination of the load bearing capacity of the zinc coating as well as the identification of suitable surface pre-treatment methods. Based on preliminary tests, the influence of steel alloy and galvanizing method on the adhesion of batch-galvanized surfaces could be investigated. Three high strength and high modulus adhesives were chosen that meet the specific needs of the construction and commercial vehicle industry. Taking into account the steel alloy and galvanizing method, different adhesive surface pre-treatments were tested and classified individually with regard to their erosive impact on galvanized surfaces. Based on a simplified cost-benefit analysis, predominantly wet-chemical surface pre-treatments were selected and applied. In doing so, a layer-selective removal in the pure zinc phase of the zinc coating could be adjusted, using light microscopic studies of metallographic sections. read more

|

|

P 967 – Reinforcement Elements for Composite Bridges

Bridges are an integral and important part of the European transportation system and fulfil high demands of national and international mobility. The technology of External Reinforcement Elements can favourably be used to build powerful composite constructions for bridges and keeping traffic impairments caused by construction works to a minimum by using prefabricated elements. External Reinforcement Elements are cut out of rolled steel sections and connected to the concrete by shear-resistant composite dowels. The scope of the previously developed design concepts is limited to single-span beams and is very necessarily to be extended to a further range by new structural applications. read more

|

|

P 1014 - Development of a concept to assess the tendency to brittle fracture of high strength bolts of large diameter in low temperature applications

High-strength structural bolting assemblies of the system HV with large diameters up to M72 are increasingly used as preloaded bolting assemblies in highly loaded steel structures. In addition to static and fatigue loads, the connections are exposed to low temperatures. It is known, that the risk of brittle fracture at low temperature applications increases with increasing thickness of the steel material. In principle, this relation also applies to increasing bolt diameters. read more

|

|

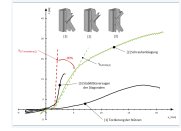

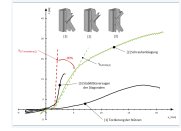

P 1062 – Investigations on load-bearing capacity of welded dual-steel connections made of mild carbon steel and high strength steel construction

The requirement towards slender and more filigree constructions with high loadings consistently leads to the application of high-strength steels. Decisive for the application of high-strength steels is, beside of the question of stability and fatigue, mainly the type of joints and connections. How to effectively realize the procedure of welding highstrength steels S690 to normal-strength steels S355 by fillet welds is still an open question. However, this is a standard situation existing in practice due to the fact that the choice of steel grade usually is adapted to the utilization and also because secondary components with small loadings are often added to the structure. read more

|

|

P 1078 – Determination of the effective shear stiffness of upright frames to ensure stability and serviceability in rack structures

For the construction of high bay warehouses upright frames build of thin-walled and cold-formed steel members are used. Due to the nature of the thin-walled steel members, the shear stiffness of the upright frames is significant reduced in comparison to the shear theory of Engesser. Until now, the fundamentals for the analytical calculation of the shear stiffness are not given. Therefore, it is common practice to determine the shear stiffness of uprigth frames experimentally. This approach is very costly and impedes the further optimisation of the highly stressed rack structures. read more

|

|

P 1067 - Definition of toughness requirements on the upper shelf for structural steel with hybrid damage mechanics based approaches

In addition to the ultimate limit state assessment which is based on ductile material behaviour the design concept in Eurocode 3 requires a toughness-orientated verification according to EN 1993-10 or DASt-RiLi 009 in order to avoid brittle fracture. The choice of steel grade, together with the requirements of the tensile test, is also regarded as guarantee for ductile material behaviour. read more

|

|

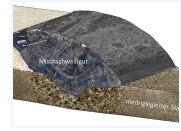

P 1099 – Dynamic design of composite bridges with integral abutments

Prediction of behaviour of railway bridges by calculation is often not satisfactory. Measurements often reveal that a structure behaves much better in reality than in calculation. Railway bridges are excited by axles with regular distances, which can cause very high dynamic loads. Therefore, eigenfrequencies and respective mode shapes, which can be excited by vertical loads, have to be predicted as accurate as possible. Damping characteristics of a structure are equally interesting. To some extend the differences between calculated and measured eigenfrequencies can be attributed to particular non-structural elements, whose contributions to system stiffness and damping cannot be considered according to current standards. read more

|

|

P 1108 – Prediction of dissimilar weld metal microstructure and properties of high manganese steels

The objective of the research project was primarily to improve the dissimilar metal welding of high manganese steels by predicting the microstructure and properties of the weld metal by means of a newly developed constitution diagram. Three economically relevant Fe-Mn steels with different alloying concepts were used as test materials. The HC340LA (1.0548) and 22MnB5 (1.5528) steels, which are widely used in car body construction, served as joining partners, as well as various high manganese metal powder cored electrodes. read more

|

|